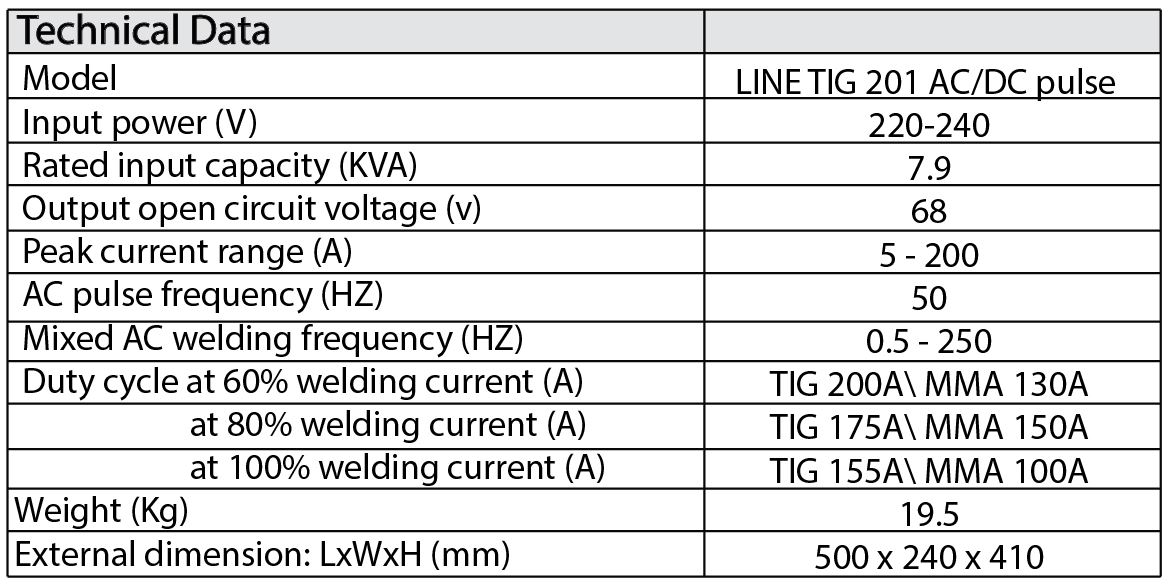

LINE TIG 201 AC/DC pulse

Line tig 201 AC\DC pulse is a digitization model can be use for MMA.

AC TIG DC TIG and PULSE TIG. The parameters can be preset and showed, welding

current and voltage can real time display.

AC TIG welding is a common method to weld aluminum, magnesium and its alloys.

IGBT duplex inverter control technology ensures stable welding current. High frequency

high voltage arc induction method. The instant arc induction successful rate is nearly 100%.

Two kinds of modes: low & middle frequency pulse control modes to realize a high

quality welding on thin sheets, different metals, different thickness, dual surface

shapes etc. Soft arc, low noise, and good arc concentration. Easy angle welding for

thin aluminum sheets; Can also implement reliable positioning welding.Protective

circuits preventing over heat, over current, lack of voltage & phase etc. are set internally

to ensure safety operation. Static plastic-sprayed surface, glabrous, hard, anti-corrosive

and non-stripping coating.Acid washing & bonderizing and static plastic-sprayed

surface, glabrous, hard, anti-corrosive and non-striping coating.

Pulse selection: Select different pulse frequency based on different welding process.

Arc collection selection: Carry out welding torch switch control by different modes.

Arc induction current: Prevent current impact when arc is inducted.Basic current:

Adjust this current can change the thermal influence to the work piece; can be used

for DC welding current as well.Arc collection current: Can reduce arc concave and

prevent welding cracks.Welding mode: Can select different welding modes for different

welding process requirement. Water-cooling, gas cooling: Select different cooling

modes so as to be matched with torch.Peak current: Can freely modulate pulse peak

current in a wide range. Pulse frequency: Can change numbers of welding joint

corrugation in the same period.Pulse width adjustment: Adjust the time ratio of pulse

current in the same period.Rising time: Welding quality can be improved while arc

creating if adjust this time.Descending time: Smooth and perfect arc collection

welding joints can obtained if adjust this time.Post flow: Adjust this time to prevent

welding joint oxidization.Clean area width: Break the Aluminum oxidization layer on

the surface of material when in AC TIG welding.

Mixed AC frequency: Change AC/DC TIG alternating output velocity.